Series 5000 Packed Tower Fume Scrubber and Air Stripper

Series 5000 Packed Tower Fume Scrubber and Air StripperBionomic counter-current packed towers are the ideal solution to air pollution problems associated with the removal of corrosive vapors, unwanted mists, noxious and odoriferous gases. By creating a counter-current flow between contaminated gases and scrubbing liquid throughout a high surface area packed bed, rapid and uniform absorption of pollutants is achieved with maximum efficiency. Series 5000 towers are designed to accept a wide variety of packings, mist eliminators and gas scrubber liquor distribution systems. This enables the scrubbers to meet a full range of applications and gas absorption requirements.

For especially troublesome low solubility gases, scrubbers can be custom engineered to include extra depth or multiple packed beds with intermediate step chemical treatment. Construction materials include thermoplastics, fiberglass reinforced plastic, dual laminate, mild steel, stainless steel, high nickel alloys, hastalloy and corrosion resistant coating and linings.

In situations where building codes limit the height of rooftop structures, or where lower absorption efficiencies are acceptable, compact horizontal Series 5500 crossflow packed scrubbers are available.

The Series 5000 Packed Tower is also available in an air stripper version for removal of VOC compounds or ammonia from water streams.

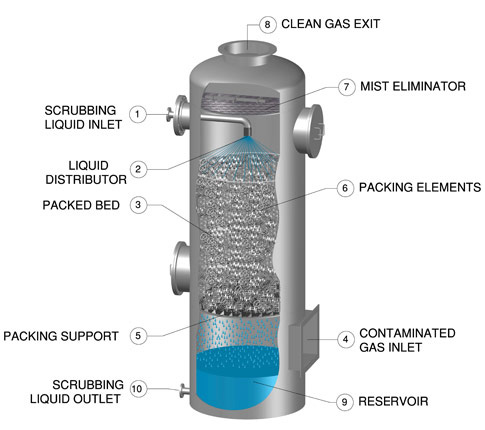

In the Series 5000 Packed Tower scrubbing liquid is introduced through a distributor (1) and is uniformly dispersed throughout the packed bed (2) The contaminated gas enters through the gas inlet (4) and proceeds upward through the packing support plate (5) into the packed bed section countercurrent to the downward flowing liquid. The high surface area packing elements (6) creates a tremendous amount of liquid films and droplets to enable rapid and uniform absorption of the gaseous contaminants for maximum removal efficiency. The contaminants can be physically absorbed in the liquid or chemically reacted with a reagent. Liquid droplets and any contaminants in mist form are coalesced and removed by the mist eliminator (7) before the cleaned gas exits through the top gas outlet (8). The scrubbing liquid then drains into the reservoir (9) and exits the unit through the liquid outlet connection (10) where it can be recirculated partially or fully depending on the service with a pump or utilized on a once through basis.

In the Series 5000 Packed Tower scrubbing liquid is introduced through a distributor (1) and is uniformly dispersed throughout the packed bed (2) The contaminated gas enters through the gas inlet (4) and proceeds upward through the packing support plate (5) into the packed bed section countercurrent to the downward flowing liquid. The high surface area packing elements (6) creates a tremendous amount of liquid films and droplets to enable rapid and uniform absorption of the gaseous contaminants for maximum removal efficiency. The contaminants can be physically absorbed in the liquid or chemically reacted with a reagent. Liquid droplets and any contaminants in mist form are coalesced and removed by the mist eliminator (7) before the cleaned gas exits through the top gas outlet (8). The scrubbing liquid then drains into the reservoir (9) and exits the unit through the liquid outlet connection (10) where it can be recirculated partially or fully depending on the service with a pump or utilized on a once through basis.

As specialists in the handling of corrosive fumes, Bionomic Industries also fabricates and installs complete corrosion resistant exhaust systems in PVC, polypropylene and fiberglass reinforced plastic. Fabrication capabilities include laboratory hoods, ducts fittings blast gates, dampers fume hoods, stacks, fans, and tanks. These items are designed to complement the Series 5000 Counter-Current Tower together with recirculation pump, chemical feed package and instrumentation.

Also see our full line of Wet Scrubbers for other appropriate types and specialized and systems for these applications

For a complete listing of the applications suited for the 5000 Packed Tower Scrubber, please visit our Industries/Applications section.

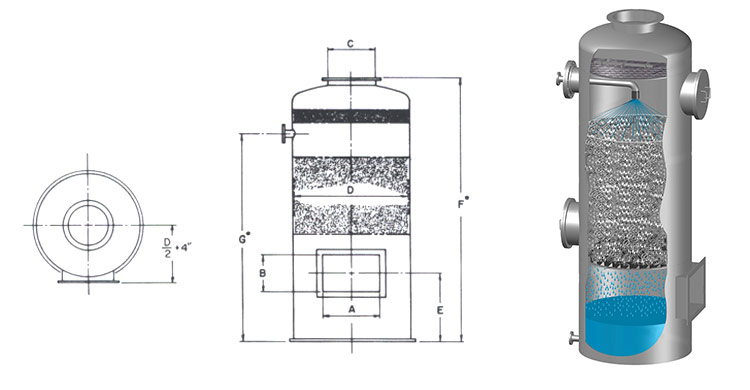

| CFM | A | B | C | D | E | F* | G* |

|---|---|---|---|---|---|---|---|

| 400 | 6" | - | 6" | 1'-0" | 1'-9" | 10'-0" | 7'-9" |

| 1,500 | 10" | - | 10" | 2'-0" | 2'-6" | 11'-0" | 8'-8" |

| 2,400 | 1'-0" | - | 1'-0" | 2'-6" | 3'-1" | 12'-0" | 9'-7" |

| 3,400 | 1'-4" | - | 1' -4" | 3'-0" | 3'-2" | 12'-6" | 9'-11" |

| 4,600 | 1'-6" | - | 1'-6" | 3'-6" | 3'-3" | 13'-2" | 10'-4" |

| 6,000 | 1'-8" | - | 1'-8" | 4'-0" | 3'-4" | 13'-7" | 10'-8" |

| 7,600 | 2'-0" | - | 2'-0" | 4'-6" | 3'-6" | 14'-6" | 11'-5" |

| 9,400 | 2'-6" | - | 2'-6" | 5'-0" | 3'-7" | 13'-8" | 10'-6" |

| 11,400 | 2'-9" | 1'-10" | 2'-6" | 5'-6" | 3'-8" | 14'-3" | 10'-11" |

| 13,600 | 3'-0" | 2'-0" | 3'-0" | 6'-0" | 3'-9" | 14'-7" | 11'-2" |

| 15,900 | 3'-3" | 2'-2" | 3'-0" | 6'-6" | 3'-10" | 15'-1" | 11'-6" |

| 18,500 | 3'-6" | 2'-4" | 3'-0" | 7'-0" | 3'-11" | 15'-2" | 11'-6" |

| 21,100 | 3'-9" | 2'-6" | 3'-6" | 7'-6" | 4'-0" | 15'-7" | 11'-9" |

| 24,100 | 4'-0" | 2'-8" | 3'-6" | 8'-0" | 4'-1" | 16'-1" | 12'-1" |

| 27,200 | 4'-3" | 2'-10" | 3'-6" | 8'-6" | 4'-2" | 16'-6" | 12'-4" |

| 30,500 | 4'-6" | 3'-0" | 4'-0" | 9'-0" | 4'-4" | 16'-11" | 12'-8" |

| 34,000 | 4'-9" | 3'-2" | 4'-0" | 9'-6" | 4'-5" | 17'-5" | 13'-0" |

| 37,700 | 5'-0" | 3'-4" | 4'-0" | 10'-0" | 4'-6" | 17'-5" | 12'-10" |

| 41,500 | 5'-3" | 3'-6" | 4'-6" | 10'-6" | 4'-7" | 17'-9" | 13'-1" |

| 45,600 | 5'-6" | 3'-8" | 4'-6" | 11'-0" | 4'-8" | 18'-1" | 13'-4" |

| 50,000 | 5'-9" | 3'-10" | 4'-9" | 11'-6" | 4'-10" | 18'-6" | 13'-7" |

Intermediate and larger sizes available. Consult factory on specific requirements.

F* and G* dimensions based on a 4 foot packing depth and may vary depending on application.

Please click here for pdf of the Bionomic Air Pollution Control, Product and Heat Recovery Systems Guide.